一. 主要用途 Application Occasions

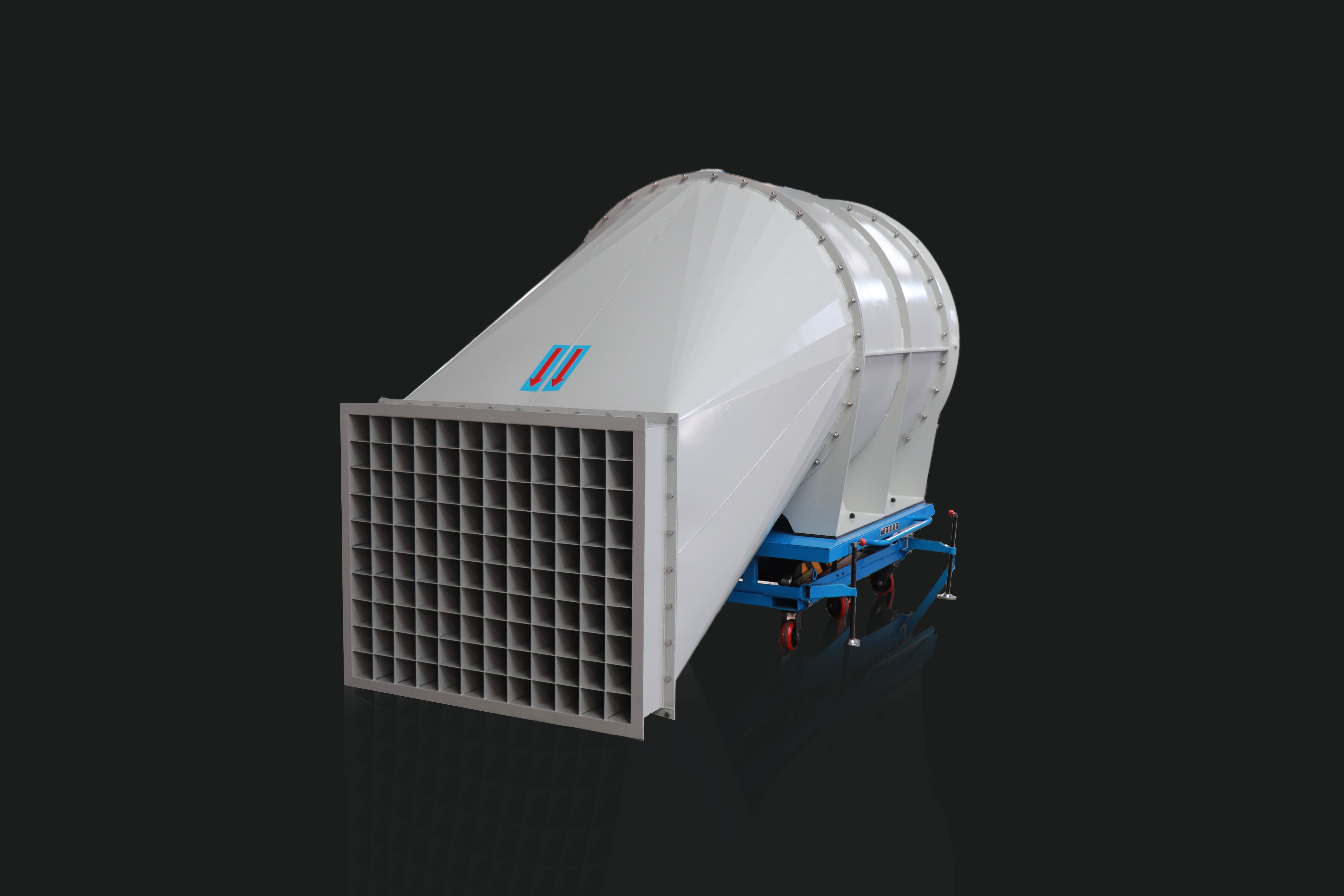

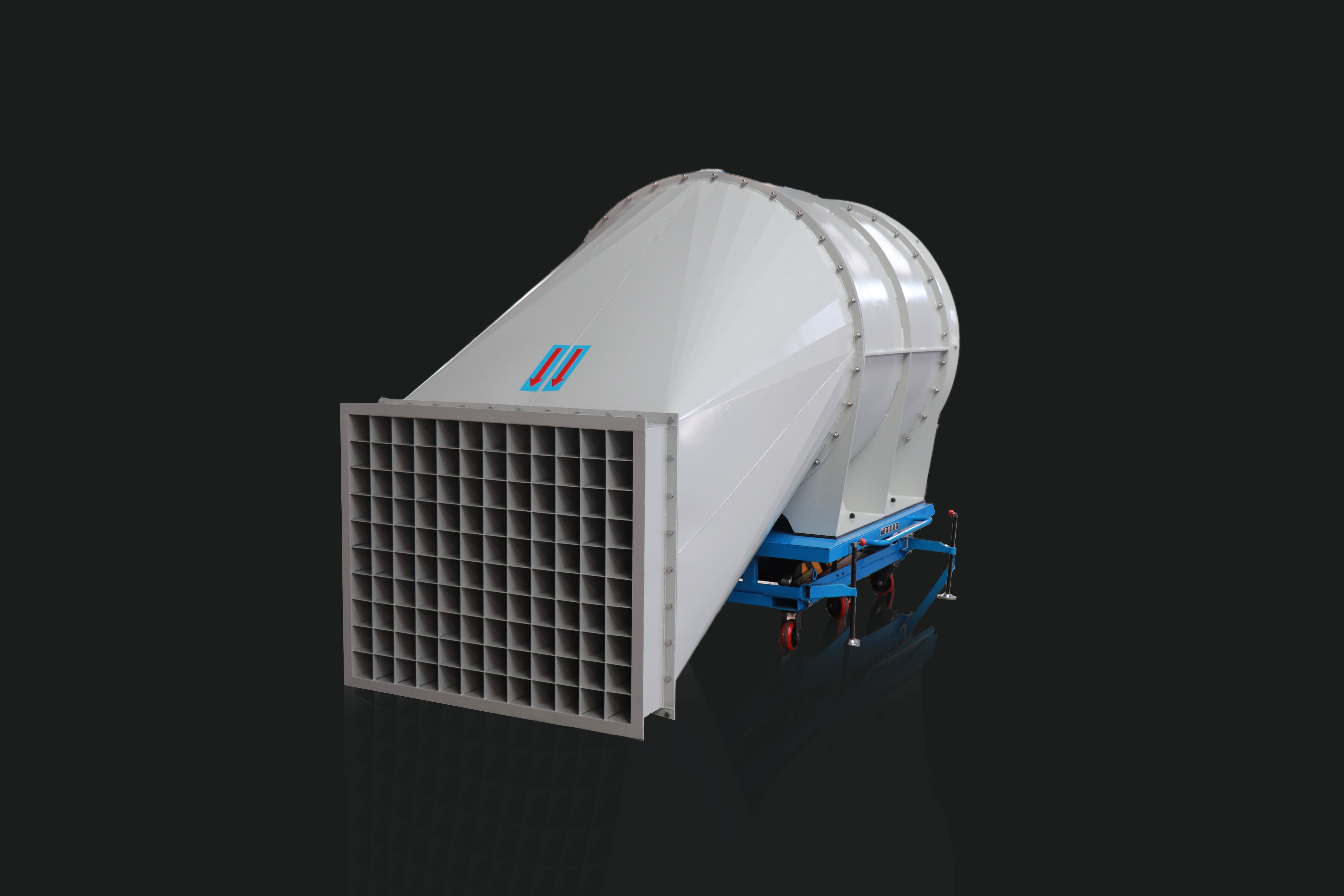

CGF风机适用于汽车装备测试,可完全模拟实际风速,对汽车、商用车等车辆进行各类性能要求的测试。

CGF fan is suitable for automobile equipment test. It can fully simulate the actual wind speed and test various performance requirements of vehicles such as automobiles and commercial vehicles.二 . 性能优势 Performance Features1.耐腐蚀:风机外表面采用特殊外表面处理,具有更好的耐腐蚀性。2.独特可移动设计:风机装备带锁万向轮,带推拉扶手,可手动在地面上移动,灵活操作,使工作范围更大;另加风机固定锁止机构,防止大风量时风机移动。3.独特上下升降设计:配电动升降台和固定支架,可根据工作环境调节风机出风口的高度,升降平稳,出风口据地最小距离100mm,最高距离800mm。1. Corrosion resistance: the outer surface of fan is treated with special surface treatment, which has better corrosion resistance.

2. Unique movable design: the fan is equipped with universal wheels with lock and push-pull armrest, which can be manually moved on the ground, and can be operated flexibly to enlarge the working range; in addition, the fixed locking mechanism of the fan is added to prevent the fan from moving when the air volume is large.

3. Unique up and down lifting design: equipped with electric lifting platform and fixed support, the height of the fan outlet can be adjusted according to the working environment, and the lifting is stable. The minimum distance of the air outlet to the ground is 100 mm, and the maximum distance is 800 mm.三 . 结构特点 Strcture CharacteristicsCGF风机主要由进口导流器、进口防护网、导叶、叶轮、电动机、外壳、出口集流器、出口变径、滚轮及电动升降台组成,风机为直接传动。输送介质为无尘空气。CGF fan is mainly composed of inlet deflector, inlet protection net, guide vane, impeller, motor, shell, outlet collector, outlet reducer, roller and electric lifting platform. The fan is directly driven. The conveying medium is dust-free air.1.进风导流罩 Inlet air guide hood

Reduce the loss of intake swirl, so that the air flow can smoothly enter the impeller.

叶片采用高强度铝合金,经过CFD模拟计算,叶型为机翼变厚扭曲叶型,具有良好的气动性能,铝合金叶片减小叶轮重量,增加轴承使用寿命。出厂前均完成严格叶轮动平衡G2.5。

The blade is made of high-strength aluminum alloy. After CFD simulation, the blade profile is a twisted blade with thickened wing, which has good aerodynamic performance. The aluminum alloy blade reduces the weight of the impeller and increases the service life of the bearing. Strict dynamic balance g2.5 has been completed before delivery.

Made of galvanized steel plate with high strength.

4.电动升降台和固定支架 Electric lifting table and fixed bracket

The fan moves up and down with electric control, and the left and right movement adopts manual control.

电机内置智能控制模块,配备高精度调速功能,具有转速恒定、效率高、寿命长、低噪声等优点。

Built-in intelligent control module, equipped with high precision speed regulation function, with constant speed, high efficiency, long life, low noise and other advantages.

进口集流器可采用不锈钢或镀锌板制作,模具液压成型,集流器弧度配合叶轮进气要求,有效减少了涡流噪声、提高整机效率。

The imported collector can be made of stainless steel or galvanized sheet, the mold hydraulic molding, the collector radian with impeller inlet requirements, effectively reduce the eddy current noise, improve the efficiency of the machine.

四 . 设计与制造标准 Design And Manufacturing Standards

-

GB/T3235-2008 通风机基本型式、尺寸参数及性能曲线

-

GB/T1236-2000 工业通风机用标准化风道进行性能试验

-

JB/T6445-2005 工业通风机叶轮超速试验

-

JB/T10214-2000 通风机铆焊件技术条件

-

JB/T6411-1992 暖通、空调用轴流通风机

-

JB/TQ339-1984 通风机产品外观质量与清洁

-

JB/T8690-1998 工业通风机噪声限值

-

JB/T10213-2000 通风机焊件质量检验技术要求

-

JB/T8689-2014 通风机振动检测及其限值

-

JB/T9101-1999 通风机转子平衡

-

JB/T6886-2005 通风机涂装技术条件

-

JB/T10178-1988 通风机现场试验

Standard specification:

-

GB / T3235-2008 basic types, size parameters and performance curves of fans

-

GB / T1236-2000 performance test of standardized air duct for industrial fans

-

JB / T6445-2005 industrial fan impeller overspeed test

-

JB / T10214-2000 specification for riveting and welding parts of fan

-

JB / T6411-1992 axial fan for HVAC

-

JB / TQ339-1984 fan appearance quality and cleaning

-

JB / T8690-1998 Noise limits for industrial fans

-

JB / T10213-2000 technical requirements for quality inspection of fan Weldments

-

JB / T8689-2014 fan vibration detection and its limits

-

JB / T9101-1999 fan rotor balance

-

Jb-2005 / t6886 Technical conditions for fan painting

-

JB / T10178-1988 field test of fan

五 . 风机性能参数表 Performance Parameters

|